3D investigation of grain boundaries in industrial grade aluminum

The versatile 6061 Al alloy is widely used for structural components in aerospace, transportation, and marine engineering due to its ease of fabrication and relatively high strength. Material defects like intergranular corrosion and stress corrosion cracking are closely related to the crystallographic characteristics of individual grain boundaries. 2D techniques such as EBSD can only statistically estimate the grain boundary plane distribution. This is why a 3D crystallographic characterization like LabDCT is necessary to extract comprehensive information for individual grain boundaries.

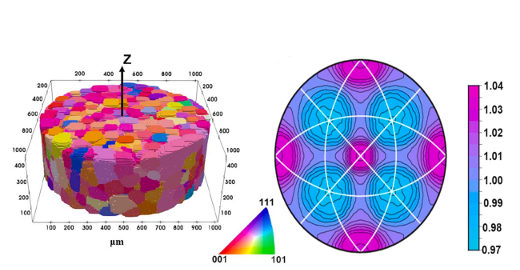

To get a more robust understanding of material performance, a group of researchers headed by Prof. Nik Chawla from Arizona State University (now Purdue University) employed LabDCT to determine the crystallographic characteristics, i.e. grain orientations, misorientations, and grain boundary plane distributions, of an extruded 6061 Al. The LabDCT data allowed extraction and correlative analysis of sample texture and grain boundary plane frequencies. Furthermore, individual grain boundaries with specific misorientations, which are assumed to be more corrosion resistant, were analyzed to find preferred boundary plane types, e.g. twist or tilt boundaries.

Materials Characterisation

By the same authors

Correlation between corrosion behavior and grain boundary characteristics by lab-based DCT