Xnovo’s technology in Nature Scientific Reports

For the first time in history, a group of researchers has been able to quantify simultaneously the orientation of individual grains and the grain growth/shrinkage kinetics during sintering of copper. The tracking of grains was made possible by Xnovo’s software, GrainMapper3D™.

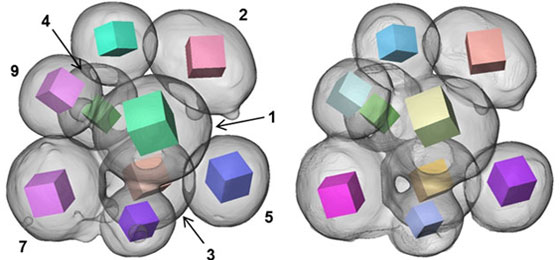

In the study, a copper powder sample was sintered and cooled a number of times. During the process absorption and diffraction images were taken to observe the morphology and rearrangement of the particles.

In addition, the GrainMapper3D was used to observe the evolution of the crystallography, and this is new:

Without destroying the sample the scientists were able to study the impact of sintering on the same piece of copper, step by step, grain by grain.

The study finds, that grain rotations are greater for surface breaking particles than for more interior ones. Both rolling and sliding particle rotations are observed. Abnormal grain growth is observed for one grain while others either grow or are consumed more gradually.

A key to knowing the properties of material

It is important to understand sintering because the method is used for the major part of complex shaped engineering components made by powder metallurgy.

The production process creates rearrangement, rotation, local deformation, diffusion and grain growth of the item, which strongly influence the final microstructure and thereby also the properties of the material.

A combination of X-ray imaging with the GrainMapper3D software offers unique insights into the microstructure of material processing and wear.

Nature Scientific Reports

Microstructural evolution during sintering of copper particles studied by laboratory diffraction contrast tomography (LabDCT)