Lab-based DCT for quantitative texture analysis of electrical steels

Electrical steels with high Si contents are widely used in electrical power transformers, motors and generators. Texture is the most important property for electrical steel as the grain orientations strongly influence the magnetisation and electrical resistance of the materials. Characterising the grain structure of electrical steels with lab-based DCT provides important complementary information to commonly used techniques such as X-ray diffraction (XRD) and electron back-scattered diffraction (EBSD) in terms of full 3D grain mapping and significant grain statistics. Case studies of using lab-based DCT to characterise the grain structure of both non-oriented and oriented electrical steels have been collected in this new publication.

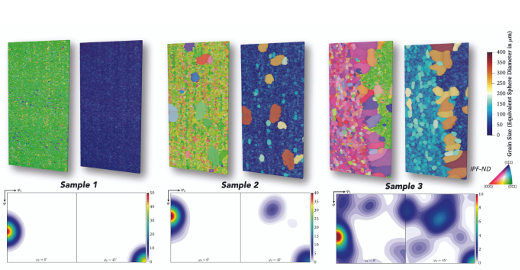

For non-oriented electrical steels, the manufacturing rolling process can introduce gradients in strain along the sample normal direction. This may lead to spatially varying annealing responses when performing further heat treatment. As demonstrated in the case studies for non-oriented electrical steels, spatial heterogeneities like the abnormal Goss-oriented grains occupying the bulk of the sample and the inconsistent grain structure at the two rolling surfaces—can be directly visualised and quantitatively analysed by means of lab-based DCT.

For grain-oriented electrical steels, mapping out the spatial distribution of Goss-oriented grains and measuring the intensity/sharpness of the Goss texture are the key characterisation tasks. Obtaining significant grain statistic for quantitative analysis can be challenging due to the enormous size of the Goss-oriented grains. With the new advanced scanning mode, HP-HART, lab-based DCT can readily accommodate large-size, high-aspect ratio samples and collect data over a large region of interest.