Multimodal investigation of 3D grain structure and local inhomogeneous deformation

Heterogeneities in the local microstructure and strain distributions in deformed metals are of critical importance for subsequent mechanical processing. It is thus essential to understand the formation of such local heterogeneities and to be able to control their development. To advance the field, it is deemed necessary to combine knowledge about the microstructures and local strain distributions; not just consider one or the other separately.

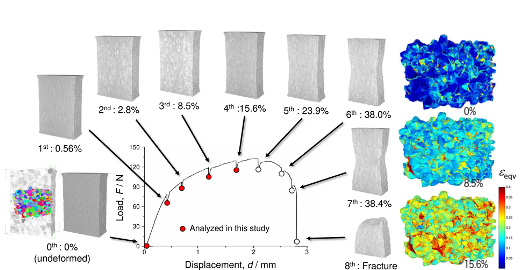

With this aim, researchers from Toyohashi University of Technology in Japan and Technical University of Denmark applied multimodal X-ray tomography, i.e. LabDCT and attenuation tomography (ACT), to non-destructively characterize the 3D grain structure and local plastic deformation behavior of a fully recrystallized Al-4mass%Cu alloy. The evolution of the internal strain distribution during tensile deformation up to 15.6% was measured in-situ by means of a microstructural feature tracking method based on ACT.

Specific interactions between neighboring grains are of critical importance for the development of the local strains

By a correlative analysis of the microstructural parameters of 855 bulk grains, it was investigated if and how the initial crystallographic orientations and sizes of the grains affect the local deformations. In addition, effects of grain boundaries were analyzed, yet only weak correlations were found. The observed complexity of the plastic deformation process largely agrees with recent synchrotron experiments for other FCC materials. All of these results indicate that grain neighbor relations significantly affect the evolution of local strains. To further advance the understanding and enable a detailed analysis of grain-grain interactions, the present 4D data (x, y, z, strain) lends itself to validate and improve crystal plasticity finite element simulations of strain heterogeneities during plastic deformation.