Systematically exploring the performance of DCT Advanced Acquisition

The acquisition of high-fidelity 3D grain maps is essential for advancing our understanding of the micromechanical behavior of polycrystalline materials. Grain orientations, grain boundary misorientations, and grain shapes play a significant role in slip transfer mechanisms and grain growth phenomena. The microstructures of challenging sample geometries have become more accessible at the lab scale with recent developments in advanced acquisition strategies for lab-based DCT.

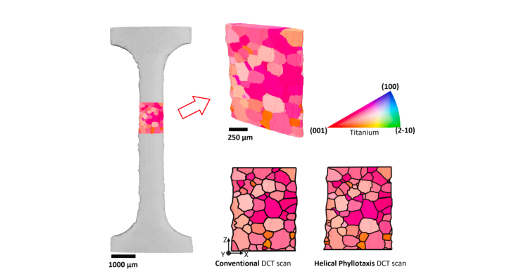

A group of researchers from Purdue University and IMDEA Materials Institute set out to systematically explore the performance of DCT advanced acquisition strategies in comparison to established techniques. A commercially pure annealed Ti sample was characterized by LabDCT to obtain 3D crystallographic grain maps that were obtained from conventional (C-DCT, stitching 5 layers) and helical phyllotaxis (HP-DCT, one continuous scan) acquisition strategies. The quality of the 3D grain maps from both acquisition strategies was assessed, and grain shape and orientation statistics were compared against the grain maps obtained from EBSD and SEM scans of the same Ti sample.

Comparable grain fidelity at significantly reduced time cost

The result assessment showed that the grain reconstructions from HP-DCT scans have comparable grain fidelity to those obtained from C-DCT scan, with the conventional scans performing marginally better in terms of grain shape and orientation but at a higher time cost: While the total scan times for HP-DCT and C-DCT scans were comparable for the present study, the total reconstruction and analysis time for the C-DCT scans was five times that of the HP-DCT scan. In the concluding words of the authors: “Our work demonstrates that HP-DCT is a very useful technique for more efficient analysis of such large samples.“