Correlation between liquid metal embrittlement and grain boundary energy revealed by LabDCT

Grain boundary wetting refers to the phenomenon that a liquid metal penetrates along the grain boundaries within polycrystalline solid metals. Replacement of the original grain boundary with the liquid layer generally causes intergranular brittle fracture in otherwise ductile metals and alloys. This is known as liquid metal embrittlement and can be a serious problem for certain materials processing scenarios such as welding and galvanizing, as well as in nuclear reactors with a spallation target of liquid metal.

Liquid metal embrittlement depends on grain boundary energy

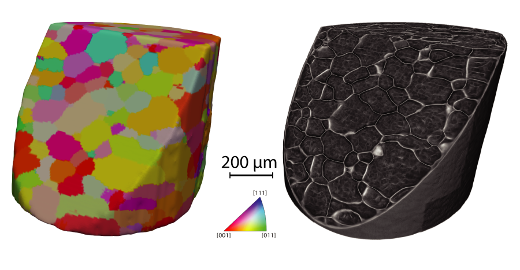

Researchers from DTU Mechanical Engineering and Xnovo have studied the penetration behavior of liquid gallium in aluminum using laboratory X-ray attenuation tomography, and related it to grain boundary properties obtained from the 3D grain map reconstructed by GrainMapper3D™. The unique results, comprising the analysis of more than 100 grain boundaries, show that it is the grain boundary energy, which determines if a boundary is wetted or not: Low energy boundaries are much more resistant to liquid gallium than higher energy ones.

The study is an excellent example of how the complementarity of attenuation tomography and LabDCT can be exploited to shed light on material properties. As a highlight, the LabDCT technique was demonstrated to readily yield both the grain boundary plane normals and the misorientation angles of a large number of grain boundaries non-destructively, thus allowing subsequent processing of the sample material and enabling studies of microstructural evolution.

Follow the publication link below for more information about the current study and the potentials of LabDCT.