Applications

X-ray Aided Engineering of Composites

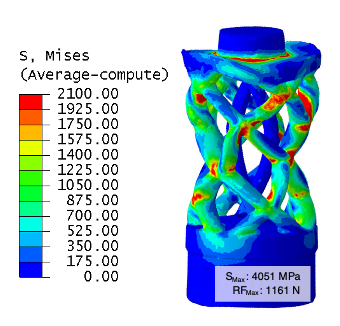

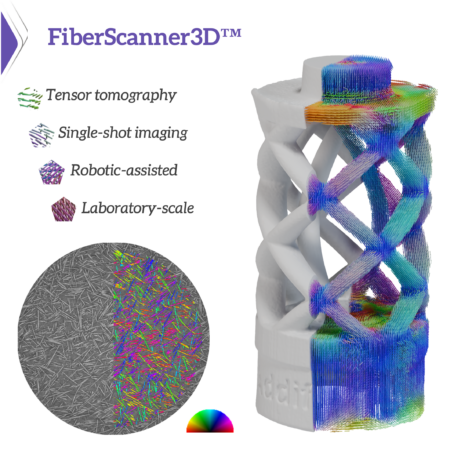

Engineering precision with high-fidelity digital twins of injection-molded components, powered by FiberScanner3D. This unique workflow captures the as-manufactured state of complex parts, integrating part geometry with 3D fiber orientation in a single scan. By replacing isotropic material assumptions with real anisotropic fiber orientation, manufacturers can identify stress concentrations and improve mechanical performance predictions.

Fuzzball Defect Detection in CFRP Components

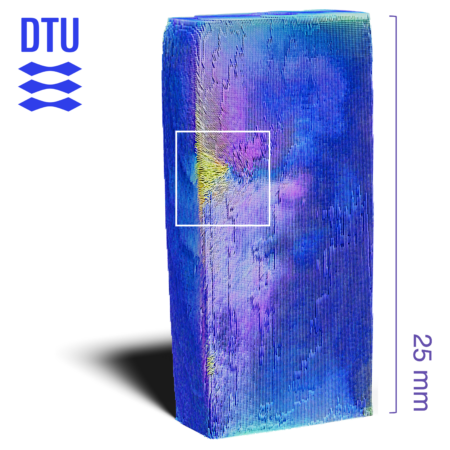

In collaboration with the Technical University of Denmark (DTU Wind), FiberScanner3D was used to detect and characterize fuzzball defects (clusters of broken fibers disrupting local alignment) in unidirectional CFRP structures. Directional dark-field imaging and 3D tomography enabled non-destructive visualization of fiber misalignments, supporting materials research and quality assurance in wind turbine components manufacturing.

Structural Analysis of Thermoplastic Laminates

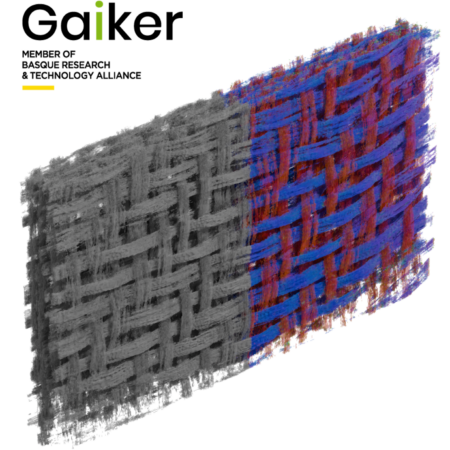

In collaboration with Gaiker, FiberScanner3D was used to analyze the internal structure of woven thermoplastic composite laminates, revealing detailed 3D fiber orientation at both the tow and individual fiber level. It enables simultaneous detection of voids and fiber packing, revealing critical defects that influence mechanical performance. This capability is valuable when comparing processing conditions, allowing for their optimization.

Structural Validation of Sustainable Packaging

FiberScanner3D was utilized to inspect the internal architecture of molded cellulose bottle caps, overcoming the low density contrast that limits standard X-ray CT in natural fibers. By utilizing X-ray scattering, the technology successfully mapped 3D fiber orientation within the complex screw threads. This is crucial for validating material and design performance, enabling the engineering of durable, sustainable alternatives to plastic packaging.

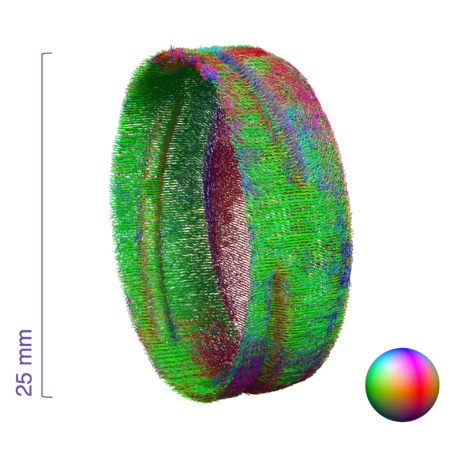

Component-scale Fiber Mapping: CFRP Hand Prosthetics

Discover the innovation of full-component fiber mapping in injection-molded Carbon Fiber Reinforced Polymer (CFRP) hand prosthetics, made possible exclusively with FiberScanner3D – advanced 3D fiber mapping technology. This 150mm tall prosthetic showcases unparalleled capabilities to access carbon fiber orientation on a component scale, ensuring optimal performance.

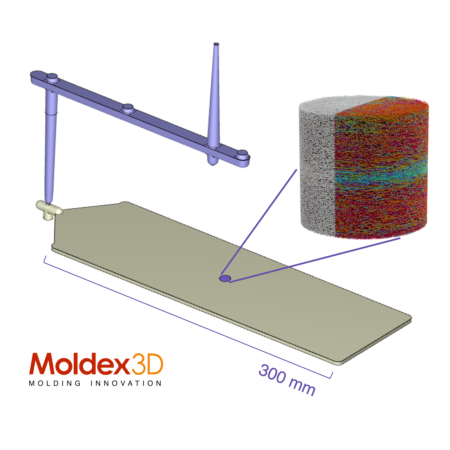

Injection Molding Process Optimization

Maximize the performance and consistency of injection-molded CFRP components through intelligent process optimization using FiberScanner3D. By analyzing fiber orientation, flow patterns, and potential areas of stress concentration, manufacturers can fine-tune mold design, injection parameters, and cooling cycles. This data-driven approach cuts waste, speeds development, and improves part performance with consistent precision.

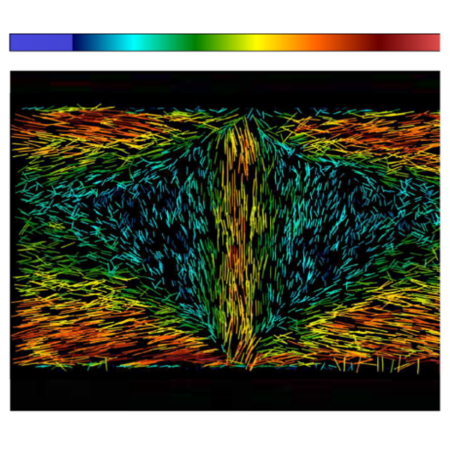

Weld Inspection in Injection-Molded Composites

Ensure the integrity of injection-molded composites with cutting-edge weld inspection powered by FiberScanner3D. This technology provides a detailed analysis of fiber orientation, degree of anisotropy, and fiber volume fraction, enhancing quality control and reliability in composite manufacturing.

FiberScanner3D – Technical Note

Unlock non-destructive, high-resolution insight into fiber architecture with FiberScanner3D. This advanced imaging technology leverages lab-based X-ray scattering and dark-field tensor tomography to reveal 3D fiber orientation in composite materials without cutting or sectioning. Ideal for research, quality control, and process development, it offers unmatched access to internal fiber structures, driving better decisions in design and manufacturing.