Efficient Characterization of Entire Fiber-Reinforced Plastic Components

Researchers from the Paul Scherrer Institute (PSI) and Xnovo Technology ApS have developed a novel x-ray imaging technology for the efficient characterization of fiber orientations within fiber-reinforced plastic (FRP) components. First results of applying the new technology to injection-molded parts is now published in the scientific journal Nature Communications.

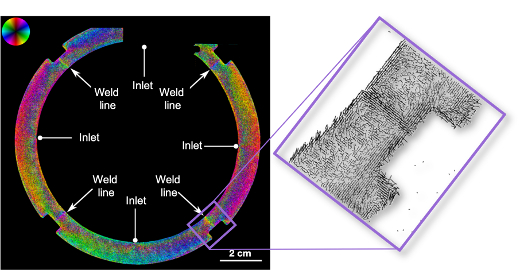

The demand for cheaper and cleaner mechanically viable alternatives to load-bearing metal parts, e.g. in the automotive and aerospace industries, keep increasing as we strive towards a more CO2-neutral transportation industry. FRPs are the natural cost-effective alternatives thanks to their high strength, corrosion resistance, and light weight. However, the mechanical potential of FRPs is not yet fully exploited. Indeed, their mechanical strength depends on the coalignment between local fiber orientation and main loading directions of the FRP part. Accessing the distribution of fiber orientations within injection-molded components is extremely important, since the way fibers are distributed and oriented locally affects the ultimate mechanical and physical properties of the final part.

Fast and cost-efficient is key

Characterization of fibrous materials is by no means a new discipline. Nevertheless, where existing x-ray imaging methods require either time-consuming scanning approaches and/or are constrained to very limited fields of view (~1 mm3), the new imaging approach – based on a novel x-ray optics design invention by researchers from PSI and developed in collaboration with Xnovo – enables fast and cost-efficient imaging of entire injection-molded parts.

“We believe that offering a characterization solution that operates on the same scale as industrial structural simulation methods – i.e. at the component scale – will help improve and shorten design cycles and result in faster time-to-market” says Erik Lauridsen, CEO of Xnovo. The excitement about these prospects is shared by Marco Stampanoni, head of the x-ray tomography research group at PSI and professor of x-ray imaging at ETH Zürich: “Our partnership with Xnovo has been a great example of how advanced technology developed at the synchrotron can be transformed into innovative lab-based solutions of benefit to both industrial and academic end-users.”

The joint development of a new method for characterization of injection-molded FRP parts is the result of an EU funded Eurostars project headed by Xnovo with participation of PSI and the Technical University of Denmark.

Nature Communications

Diffractive small angle X-ray scattering imaging for anisotropic structures