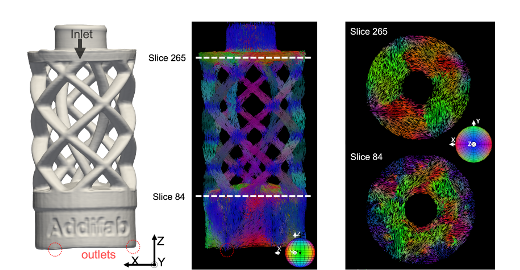

Full-component 3D fiber mapping of fiber-reinforced composites

An efficient and industry-friendly solution for non-destructive 3D fiber mapping is now realizable thanks to a novel robot-assisted X-ray imaging technology. First results of applying this solution to an injection-molded fiber-reinforced plastic (FRP) part has been published in the scientific journal Composites Part B.

FRPs are strong and lightweight materials comprised of a polymer matrix reinforced with fibers such as carbon, glass, or natural fibers like hemp or wood. FRPs are becoming an increasingly popular alternative to conventional structural materials in vast industrial applications. In fact, the load-bearing capabilities of the FRP-based parts strongly depend on the local fiber alignment in the final product. However, existing solutions for 3D fiber characterization have limited capabilities to efficiently provide access to representative volumes.

The new 3D fiber mapping solution developed as a collaboration between Xnovo Technology, the Paul Scherrer Institute, and the Technical University of Denmark is a big step towards much anticipated full-component fiber characterization. Based on specialized X-ray optics and high-precision robotics, this technology provides fast and efficient 3D fiber characterization over large volumes, directly transferrable to industrial settings.