Industrial Steel Process Monitoring with LabDCT

In the steel processing industry it is of the utmost importance to both detect and understand potential microstructural heterogeneities caused by the various processing steps. The heterogeneities are often observed at substantially larger length scales than the grain size, and can hence only be detected with 3D characterization techniques able to map macroscopic samples consisting of thousands of grains.

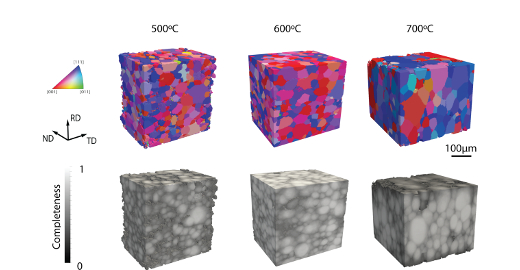

A group of researchers headed by professor Masao Kimura from KEK in Japan recently applied LabDCT to map the grain size and texture of severely cold-rolled pure iron after recrystallization at annealing temperatures of 500, 600 and 700°C. The average size of the recrystallized grains in the center region of the sample was found to be 20–30% larger than at the rolling surfaces, as illustrated in the animation below for the sample annealed at 600°C. This suggests that the grain nucleation is driven by the large strain caused through severe rolling, with a larger number of recrystallization sites at the rolling surfaces compared to the center region.

In summary, for process optimization in industrial steel research, LabDCT provided crucial information for detecting microstructural heterogeneities and understanding the underlying nucleation and recrystallization mechanisms.