Harnessing LabDCT to understand dynamics of liquid metal penetration

When a liquid metal like gallium penetrates along the grain boundaries within a polycrystalline solid metal like aluminum, replacement of the original grain boundaries with the liquid layer generally causes intergranular brittle fracture in otherwise ductile metals and alloys. This is known as liquid metal embrittlement and can be a serious problem for certain materials processing scenarios such as welding and galvanizing, as well as in nuclear reactors with a spallation target of liquid metal.

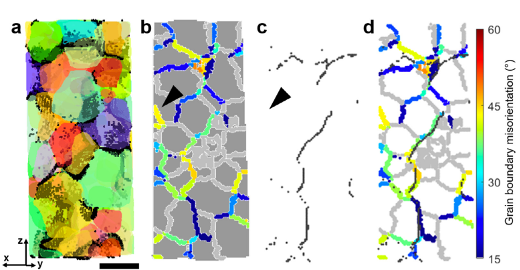

With the goal of understanding the dynamics of this process, and thereby contributing to grain boundary engineering of embrittlement-resistant materials, a group of researchers headed by Ass. Prof. Ashwin Shahani from University of Michigan performed an in-situ study of Ga penetration in an Al polycrystal. First the 3D grain structure of the Al polycrystal was mapped using LabDCT, and then the Ga penetration was followed every hour for two days using laboratory X-ray attenuation contrast tomography (ACT).

Liquid metal embrittlement depends on high-angle grain boundary connectivity

The unique results of the study, comprising the analysis of more than 800 grain boundaries, show that the onset of liquid metal embrittlement happens through the high-angle grain boundary network. Upon prolonged annealing, Ga diffuses from the high-angle grain boundaries into the bulk of the Al matrix through the low angle grain boundaries and dislocations.

The study is an excellent example of how the complementarity of ACT and LabDCT can be exploited to shed new light on materials dynamics. As a highlight, essential microstructural parameters for the dynamical analysis such as grain boundary misorientations and connectivity, were straightforward to extract from the 3D grain map created using GrainMapper3DTM.

Acta Materialia

By the same authors

Grain boundary percolation studied by LabDCT

Dynamics of particle-assisted abnormal grain growth