Grain structure evolution during heat treatment of a semisolid Al-Cu alloy studied with lab-based DCT

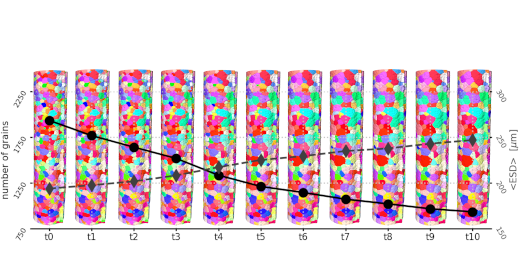

3D experimental data of simultaneously high temporal and spatial resolution is key to validating computational models of materials phenomena. In collaboration with Dr. Jules Dake from Ulm University in Germany we exploited lab-based DCT to capture the evolution of grain structure over ten interrupted heat treatments of a semisolid Al-Cu alloy. The time resolved response measured on the Al-Cu model system provides insights into the rearrangement, densification and coarsening of powder compacts at late-stage sintering.

The wealth of the experimental data lends itself particularly well to investigations of both grain size and orientation (rotation) evolution. A statistical study of the evolving grain structure revealed that the disappearing grains are generally among the smaller ones at the beginning of the experiment. In addition, the rotations of individual grains are typically small fluctuations irrespective of grain size, but when an abruptly large rotation is observed, it is more likely to occur for a smaller grain at the last annealing step(s) before the grain vanishes. The movie below shows one such small grain, which rotates more than 5 deg before it vanishes (hence the IPF colour change from green to turquoise), along with two of its stable neighbours (in yellow/grey).

Learn more about the experimental parameters used in the 4D lab-based DCT study from our GrainMapper3D Spotlight.

4D open-access dataset

As a contribution to the continued development of predictive grain coarsening models, the grain maps of all eleven temporal states have been made publicly available to the scientific community for further analysis via the Materials Data Facility.

Tomography of Materials and Structures