Visualizing Materials Interfaces in 3D

Visualizing Materials Interfaces in 3D

By Ashwin J. Shahani, Assistant Professor at the University of Michigan

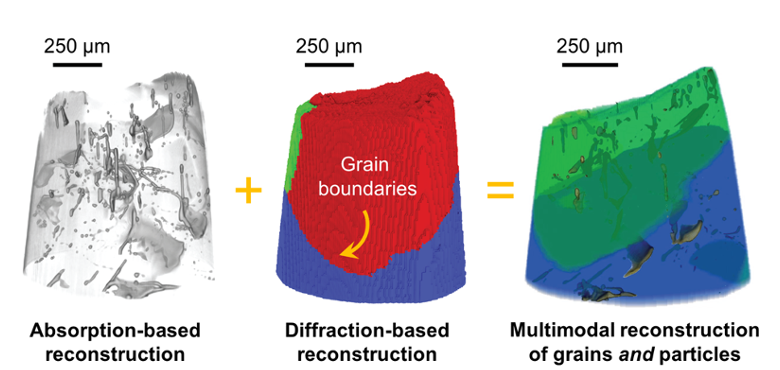

“Having the LabDCT is quite instrumental for my group, because we can verify the theories and simulations of grain boundary structure and motion with very high precision. It allows us to perform in situ tests such as annealing to see how the polycrystalline material evolves in time, without having to repeatedly destroy the sample. In addition to grain structure, we can capture the locations of second-phase particles (such as impurities) on the same device, and on a large variety of materials.”

LabDCT is suited for a diverse array of materials

“Our group is interested in a number of problems that can be immediately addressed using the LabDCT on campus: For one, we seek to uncover the complex network of interfaces and particles in semiconductors, which is critical for their performance in commercial applications, e.g., solar cells. Our work with polycrystalline silicon has addressed this issue.

A second interest is to understand how aluminum-based alloys evolve under the application of heat. In certain scenarios, one grain in the polycrystal may catastrophically “eat up” its neighbors, thereby leading to materials failure. In both projects, the fundamental question is, what do the interfaces look like in 3D and based on the network of the interfaces, what does this means for performance?

Other groups on campus are also quite interested in the capabilities of LabDCT, and particularly for battery materials. There is interest over a wide variety of applications that underlines the power and compatibility of LabDCT for different experiments.”

GrainMapper3D version 2.0 works very well

“We have done a lot of benchmarking tests on the GrainMapper3D version 2.0 and it works well for us. We have now determined what samples are best for the equipment and the ensuing reconstruction, preparing for very long in situ experiments to study interfacial evolution as a function of time in repeated anneal cycles.

When I first started at Michigan, we used to do all our experiments at the synchrotron user facility and come back with loads of data. The LabDCT is right here, accessible, within reach, providing data around the clock. For us that is a major benefit. Even if we need the synchrotron for ultrafast experiments, we use the LabDCT for trial runs to precheck the microstructure of our samples and determine if they are suitable for the synchrotron experiments.”

The extra push

“Xnovo have always been very helpful debugging the reconstructions, whenever we needed the extra push. It’s always great to collaborate with them and really adopt the LabDCT technique here on campus. We extend our thanks to Erik, Nicolas, Jun, and the rest of the scientists at Xnovo.”

Interested in more cases?

Deformation and granular mechanics, Stephen Hall, Lund University

Metal failure and microstructure, Dorte Juul Jensen, Technical University of Denmark